Diagnosing and repairing leaks in turbo back exhaust systems involves visual inspections, identifying common leak points like gaskets and connections, using sealants or replacing parts. Regular maintenance, timely repairs, and upgrades to high-performance components prevent further damage, ensuring optimal performance and reliability for these systems.

Uncovering leaks in your turbo back exhaust system is crucial for optimal vehicle performance. This comprehensive guide navigates the intricacies of these advanced systems, which combine turbocharged engines with a rear exhaust configuration. By understanding their unique design and identifying common leak sources—from gaskets to welds—you’ll gain the tools to effectively diagnose and resolve issues promptly. Whether you’re a professional mechanic or an enthusiastic DIYer, this knowledge is essential for maintaining your turbo back exhaust system’s efficiency and longevity.

- Understanding Turbo Back Exhaust Systems

- Identifying Common Leak Sources

- Diagnosing and Resolving Leaks Effectively

Understanding Turbo Back Exhaust Systems

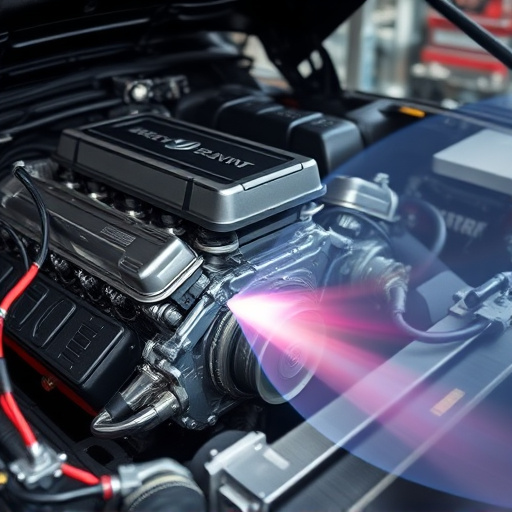

Turbo Back Exhaust Systems are designed to enhance the performance and sound of your vehicle’s engine. Unlike traditional cat-back exhaust systems that replace only the muffler and tailpipe, turbo back systems replace a significant portion of the exhaust pipeline, starting from the catalytic converter (or turbine outlet) all the way to the rear end. This includes various components like headers, turbos (in turbocharged vehicles), midpipes, and often, suspension components designed for enhanced performance.

Understanding how these systems work is crucial when diagnosing leaks. Leaks can occur at connections between these components, which may be sealed with gaskets or clamps. Unlike a cat-back exhaust leak, which might emit a drone or hum, turbo back system leaks can produce a wide range of sounds, from high-pitched whines to deep roars, depending on the location and severity of the leak. Regular maintenance checks, inspecting for loose connections, and understanding the unique sounds your vehicle makes under different conditions are key steps in diagnosing and addressing any leaks in your turbo back exhaust system.

Identifying Common Leak Sources

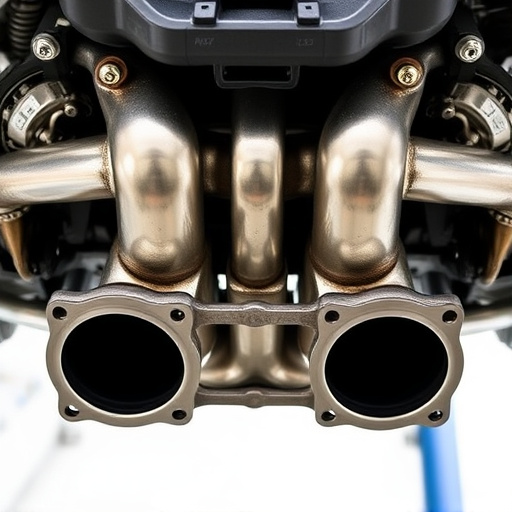

Leaks in a turbo back exhaust system can originate from various points along the process, making identification crucial for effective repairs. Common sources include the connections between the turbocharger and the exhaust manifold, where high-pressure gases can escape due to loose or damaged gaskets. Another frequent issue is leaking exhaust mufflers or muffler tips, which may be caused by worn-out or cracked components. Performance exhaust systems, with their additional components and higher flow rates, can also introduce unique leak points, particularly around high-stress areas like the catalytic converter or back pressure valves.

Visual inspection and listening for unusual sounds are effective initial steps in identifying leaks. However, using a pressurized air test or a specialized leak detection solution can provide more precise results. By zeroing in on these common sources, technicians can efficiently diagnose and address issues, ensuring optimal performance and reliability of the turbo back exhaust system.

Diagnosing and Resolving Leaks Effectively

Diagnosing leaks in a turbo back exhaust system is crucial for maintaining optimal performance and efficiency. Start by visually inspecting the turbocharger, downpipe, and exhaust components for any signs of damage, cracks, or loose connections. These visible indicators can often point to the source of the leak. Check for common leak points like gaskets, welds, and connections between different parts, especially around the turbocharger housing and exhaust flanges.

Once identified, resolving leaks effectively requires a systematic approach. For small gaps, applying a high-quality silicone sealant or re-welding damaged areas can be sufficient. However, for larger or more complex leaks, replacement parts might be necessary. Upgrading to high-performance air filters, coilover kits, or intake components can also contribute to overall system integrity and improve turbo back exhaust performance. Regular maintenance and timely repairs are essential to prevent further damage and ensure a reliable, leak-free turbo back setup.

Diagnosing leaks in a turbo back exhaust system is a crucial step in maintaining its performance. By understanding the common leak sources and employing effective diagnostic methods, car owners can ensure their vehicles run efficiently. Regular maintenance and prompt repair of any leaks will not only prevent potential damage but also optimize engine power and fuel economy, making it an essential task for every vehicle owner with a turbo back exhaust system.