A turbo back exhaust system enhances performance in turbocharged vehicles by directly routing exhaust gases through the turbocharger. Key components include headers, optimized pipes, and muffler tips with critical pipe diameter balance to avoid bottlenecks or excessive noise. Larger diameters boost power at higher RPMs while smaller ones offer quieter daily driving; selection impacts gas flow efficiency, heat transfer, resistance, and vehicle clearance constraints. Balancing performance, sound, and design is crucial for optimal fitment and maximizing engine output in a turbo back exhaust setup.

Selecting the right pipe diameter for a turbo back exhaust system is key to optimizing engine performance and efficiency. This guide explores the fundamentals of turbo back exhaust systems, outlining their unique benefits in enhancing power and improving fuel economy. We delve into critical factors influencing diameter selection, including vehicle type, engine specifications, and desired performance outcomes. Understanding these aspects ensures you make an informed decision for optimal turbo back exhaust setup.

- Understanding Turbo Back Exhaust Systems

- Factors Affecting Pipe Diameter Selection

- Optimizing Performance through Proper Diameter Choice

Understanding Turbo Back Exhaust Systems

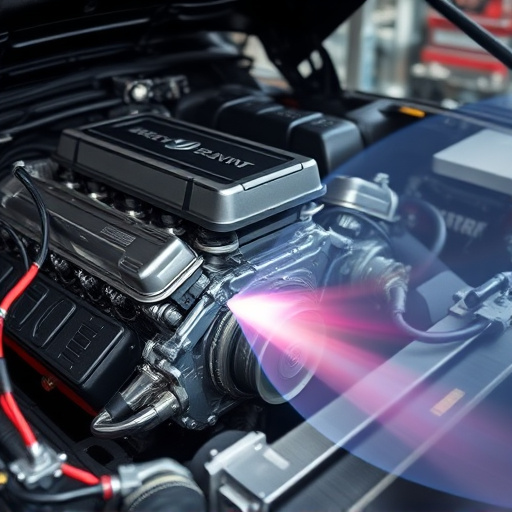

A turbo back exhaust system is a performance upgrade for vehicles equipped with turbocharged engines. Unlike traditional exhaust systems that discharge gases from the engine to the muffler, a turbo back setup directs these gases directly through the turbine of the turbocharger, enhancing power and torque output. This design optimizes efficiency by keeping back pressure low, allowing the turbo to spin faster and compress more air into the cylinder, which in turn results in increased horsepower.

Key components of a turbo back system include high-flow headers, performance exhaust pipes, and often, visible muffler tips for aesthetic appeal. Unlike stock systems that focus on quiet operation, performance exhausts prioritize flow efficiency, ensuring gasses exit the engine quickly to maximize power. As such, choosing the right pipe diameter is crucial; too small, and backpressure can hinder performance; too large, and excessive noise levels may result. Selecting a pipe size that balances these factors, often with input from experienced mechanics, ensures optimal performance and enhances the overall driving experience, complementing other upgrades like powerful brakes for enhanced control during acceleration.

Factors Affecting Pipe Diameter Selection

When selecting a pipe diameter for a turbo back exhaust system, several factors come into play. The primary consideration is the desired performance and sound levels. A larger diameter promotes better airflow, resulting in increased power and engine response, especially at higher RPMs, which is ideal for those seeking an aggressive turbo back setup. Conversely, smaller diameters offer quieter operation, making them more suitable for daily driving or areas with noise restrictions.

Furthermore, the choice should account for the overall exhaust system design, including the cat-back or coilover kits used. The combination of pipe diameter and other components directly influences gas flow efficiency. Factors like backpressure, heat transfer, and resistance to flow all play a role in determining optimal diameter. Additionally, the physical size and clearance constraints of the vehicle’s underbody must be considered to ensure proper fitment without compromising performance or safety.

Optimizing Performance through Proper Diameter Choice

Choosing the right pipe diameter for a turbo back exhaust system is key to optimizing performance. A larger diameter allows for smoother airflow, reducing backpressure and enabling your turbocharged engine to breathe more efficiently. This translates into increased horsepower and torque, particularly at higher RPMs. Conversely, an overly small diameter can restrict airflow, resulting in reduced power gains and potential engine knocking.

Selecting the ideal diameter requires balancing these factors against other considerations like sound level (impacted by muffler tips and cold air intakes) and weight (larger pipes often add significant bulk). Coilover kits and other suspension upgrades may also influence your decision, as they can affect the vehicle’s overall performance dynamics. Ultimately, consulting with experienced tuners or researchers can help you make an informed choice that maximizes both engine performance and drivability in your turbo back exhaust setup.

When selecting pipe diameter for a turbo back exhaust system, understanding both the vehicle’s performance requirements and the practical considerations is key. By carefully considering factors like engine power, exhaust flow, and temperature, you can optimize your turbo back setup for enhanced performance. Remember, the right diameter choice not only improves speed and efficiency but also contributes to a smoother, more enjoyable driving experience in your turbocharged vehicle.